Ladles, slag pots and other technological and non-standard equipment

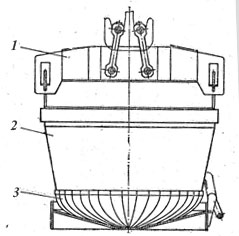

Charging bucket

Main parts of the bucket:

- travers;

- tub;

- bottom.

The bottom is welded from steel sheets and has three brackets for clamps mounting with the help of which the bottom is connected to the tub. The bottom fixes the plate chains of the tub during transportation and loading the tub by charge materials.

Travers is a welded construction with cargo brackets for the tub clamping and the bracket for attaching to the crane hook. Travers is used for transportation of the loaded and empty tub.

The tub consists of the welded shell ring and bottom made from flexible plate sectors. Sectors are pivotally connected to the shell ring at the wide end. The narrow end of the sector has the eyelet. Locking chains are threaded through all of the eyelets to lock the bottom. One end of chains is permanently attached to the sector, the others are closed to the lock with the bolt connected to the lever. During pressing the lever the bolt gets of the chain and the bottom of the tub is opening.

Currently our company offers the following standard sizes of buckets, with the following characteristics.

| № | Parameter name |

1,5t |

3,0t |

6,0t |

12,0t |

1 |

Charging bucket volume, m3 |

1,3 |

2,6 |

5,4 |

12,0 |

2 |

Bulk density of the charge mix, kg/m3, not less than |

1150 |

1150 |

1120 |

1 000 |

3 |

Load capacity, kg, not more than |

1500 |

3000 |

6000 |

12 000 |

4 |

Charging bucket weight, kg |

1480 |

1790 |

3150 |

7 000 |

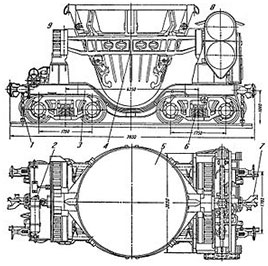

Slag car

Slag car consists of the slag ladle mounted on the specially designed platform. It is used for molten slag transporting from the blast furnace or open hearth furnace to the slag dump.

The drawing shows a slag car with the capacity of 16 m3, developed in the middle of the twentieth century. Slightly redesigned version of the slag car is widely used at the steel plants in Ukraine and in the countries of the former Soviet Union.

- hook for the slag car attaching to the rails during ladle canting;

- air-brake;

- platform;

- support ring;

- ladle;

- car;

- automatic coupler;

- ladle turning-over mechanism (at the modern slag cars it has a slightly different design);

- sectors.

Slag pot

Slag pot is a metal bucket used for the collecting of the liquid slag flowing out of the working window of the steelmaking furnace during the smelting process. It is mounted under the furnace on the car moving at a special flyover.